Technical Report

Feeling the potential of LUMEX

A new form of “manufacturing” that is completely

different from anything that’s been done before.

Matsuura’s hybrid metal 3D printers can do all this.

Complex molds that were previously impossible to create

can now be integrated using LUMEX ‘s hybrid process.

What previously required assembling 85 parts and taking two to three months to produce

can now be done in about 180 hours.

Check out the possibilities of LUMEX with some modeling samples.

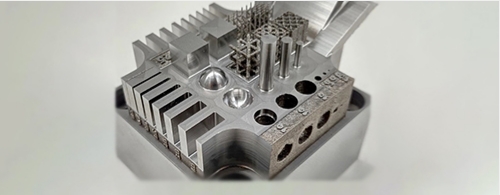

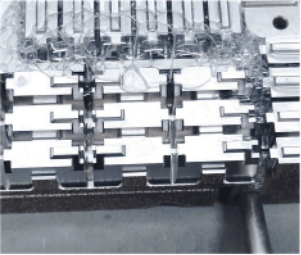

Modeling performance sample

Please take a look at the “Modeling Performance Sample” sample work to measure LUMEX performance.

Key Point

- A wide variety of shapes that can be realized with LUMEX are integrated and visualized in one model.

Data Sheet

Machine used: LUMEX Avance-25 ( 45,000min-1Spimdle, Laser Power 500W )

Sintering performance sample (72×60×H31 mm)

|

Material |

Matuura MaragingⅡ |

|---|---|

|

Weight |

420 g (Without Baseplate) |

|

Time |

Sintering: 5H 40min Total: 38H 30min |

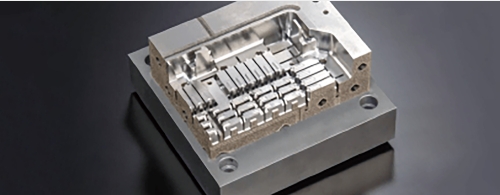

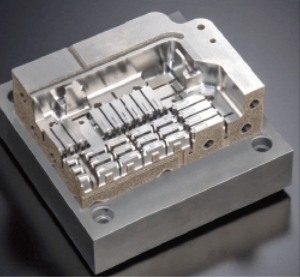

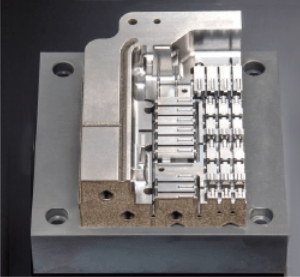

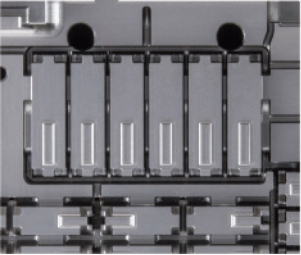

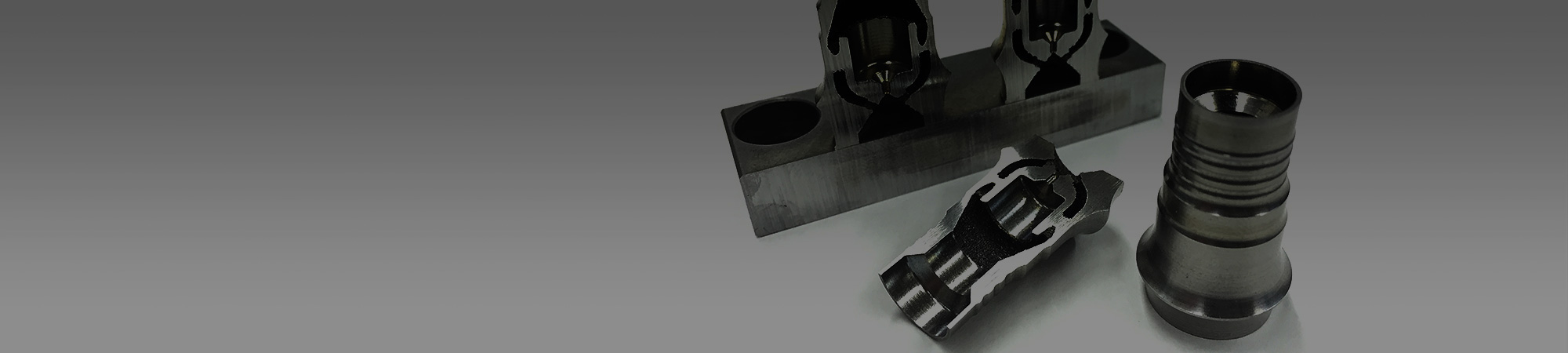

Resin molding die

Please take a look at the “Modeling Performance Sample” sample work to measure LUMEX performance.

Key Point

- Conventional products require 85 parts to assemble⇒2~3 months for production

- Integrated by LUMEX hybrid process

- Full size(160×245×68mm)is produced in approx240 hours

Data Sheet

Machine : LUMEX Avance-25 ( 45,000min-1Spindle, Laser 500W )

Plastic molding 1/4cut model (80×122.5×H68 mm)

|

Powder |

Matsuura maraging Ⅱ |

|---|---|

|

Weight |

2 kg (Without Baseplate) |

|

Running time |

Sinter: 12H 20min Total: 65H 50min |

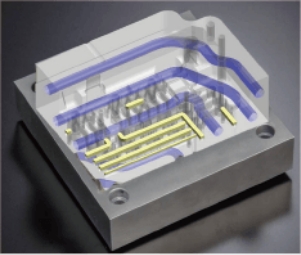

Key Point

- 3D cooling channels are placed around the periphery and at the bottom

- Porous structure arranged to exhaust gases from the bottom of the groove

- Groove processing with a minimum width of 0.9 mm and a maximum depth of 12 mm