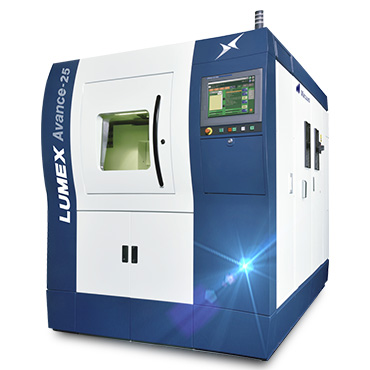

LUMEX Avance-25

The World’s First Hybrid Metal 3D Printer (Since2002)

HIGH SPEED

High output fiber laser

Standard500W

Option1kW

The sintering and milling time is shortened by improved powder distribution speed and optimized galvano control / sintering conditions and milling paths. A maximum build speed of 35 cc/h*1*2 can be achieved.

1:The above is the calculation value, not the guaranteed value.

2:Laser output 1 kW

Pre-milling powder suction

By removing metal powder around the built part before the start of milling, a faster cutting feed rate can be used, thereby shortening the milling time.

※Patents relating to “hybrid laser sintering & milling device” used under license from Panasonic Corporation.

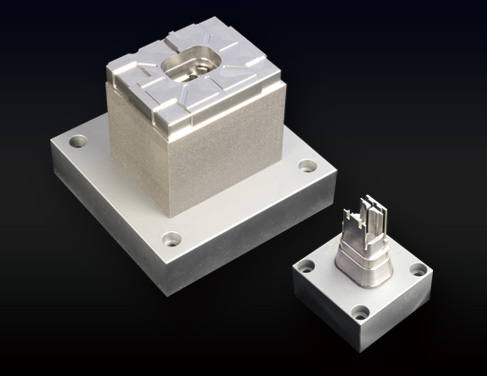

LARGE CAPACITY

MAX. WORK SIZE

150kg

- Max. work size

- W256mm×D256mm×H300mm

- Max. work weight

- 150kg

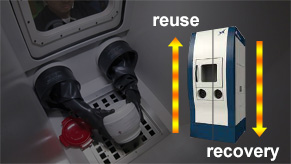

AUTOMATION

Option

APR System(Automatic Powder Recovery System)

Powder supply, collection and reuse can be fully automated without the need for the operator to directly touch the powder. Excess powder that remains after sintering is automatically sieved and reused for subsequent sintering.

SPEC

Hybrid Metal 3D Printer LUMEX Avance-25 |

Hybrid Metal 3D Printer LUMEX Avance-60 |

|

|---|---|---|

| Laser oscillator | Yb fiber laser | Yb fiber laser |

| Laser Power:W | 500Standard 1000Option |

1000Standard |

| Max. Work Size: mm |

W256 × D256 × H300 |

W600 × D600 × H500 |

| Max. Part Size: kg |

150 |

1300 |

| Spindle Speed:min-1 | 45,000Standard | 45,000Standard |

| Travel(X/Y/Z):mm | 260/260/100 | 610/610/100 |

| Feed Rate(X/Y/Z):m/min | 60/60/30 | 60/60/30 |

| NC System | i-Tech Avance |

i-Tech Avance |