LUMEX Solution

Solution of Mold Manufacture

Manufacturing highly advanced molds in a single process.

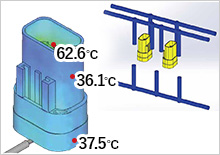

Waterproof Connector

- Machine used

- LUMEX Avance-25

- Material

- Matsuura Maraging Ⅱ

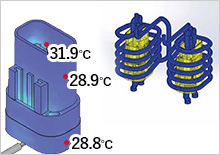

Injection molding cycle time reduction

Conventional water channels

3D water channels

Solidification within the same cooling times

Integrated cooling channels can be created internally on any componentor mold. Compared to conventional post process cooling channels, these channels exhibit far superior and efficient cooling, contributing to a significant reduction in injection molding time.

Injection molding cycle time reduction by 33%

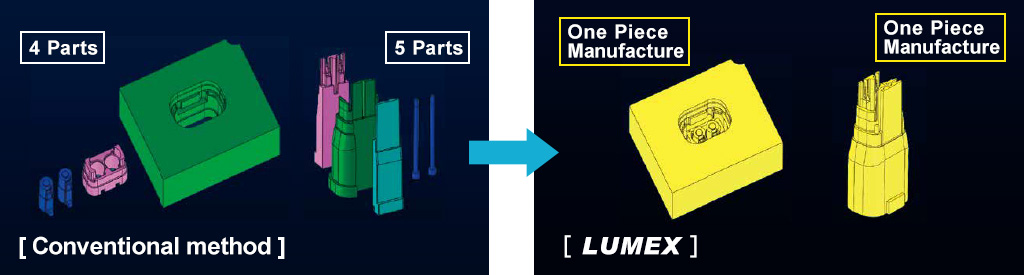

Integrated one piece mold production

Even complicated molds can be manufactured in one piece,thus eliminating assembly and adjustment, and making it possible to produce molds with no dimensional errors that may be caused by conventional assembly processes.

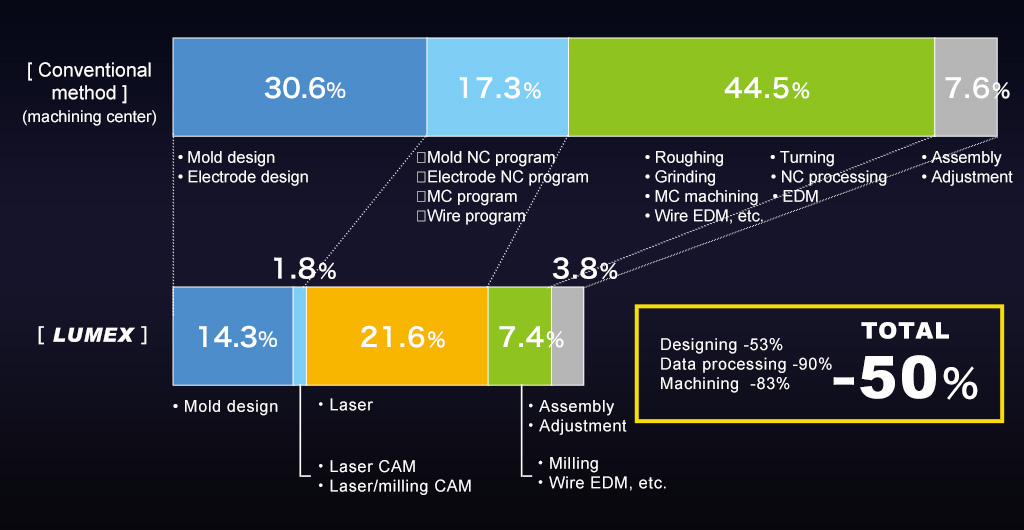

Reduction in lead time from design to finish

The LUMEX series can produce molds in one piece and eliminates the need for EDM, assembly or adjustment. In addition, the time required for design and CAM processing can be shortened drastically. Even with deep-ribbed molds, the design time is reduced by approx. 53%, CAM time by 90%, and manufacture time by 83%. In total, a 50% reduction in mold production time is achieved compared with conventional methods.

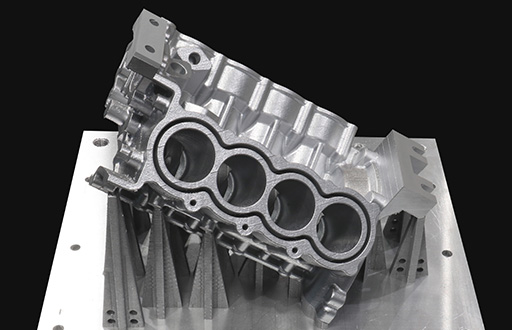

Solution of Parts product

Internal lattice structures never before possible can be realized.

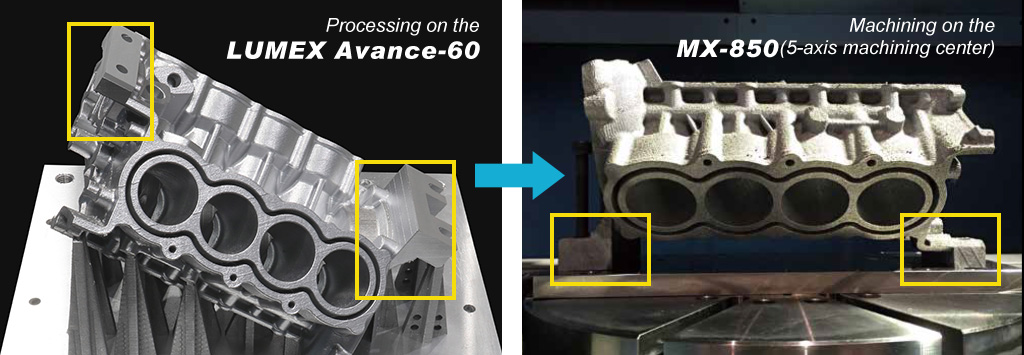

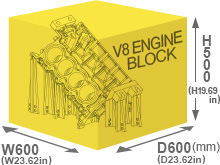

V8 Engine Block

- Machine used

- LUMEX Avance-60

- Size

- W424×D317×H339mm

- Material

- Matsuura Aluminum Si10Mg

Highly Functional Part Manufacturing

Parts with a complicated internal structure, hollow light-weight parts, large-sized parts such as engine blocks, etc., can be produced.

Large Capacity・High Speed

1 kW fiber laser provided as standard

Not only upsizing but also speedup available thanks to improved power distribution speed

Work volume : 3,590cc

Build speed : 40cc/h

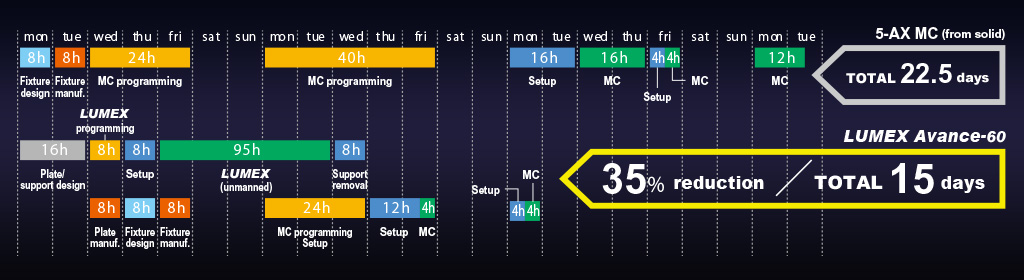

Drastic Lead Time Reduction

When manufacturing parts that require cutting processes on a machining center, the datum surface and base block necessary for such processes can also be built and machined, which reduces the setup time and costs, thereby shortening the lead time drastically.